Product classification

Contact Us

- Advisory Service Hotline:86-534-2729828/2729829

- Technical Service Hotline:86-534-2729823

- after sales service complaints:86-178-5349-1413

- Sales Director Liu:86-188-0534-2708

- Marketing Department Yang Manager:86-187-6606-9289

- Human Resources Department:86-188-6606-6097

- E-mail:xbs@sdxiaoboshi.com

- Address: No.1, Xiao Bo Road, Chongde 11th Avenue, south of Tianqu East Road, Dezhou City, Shandong Province

Microbial detection instrument

Key words:

Detailed Description

Product Introduction:

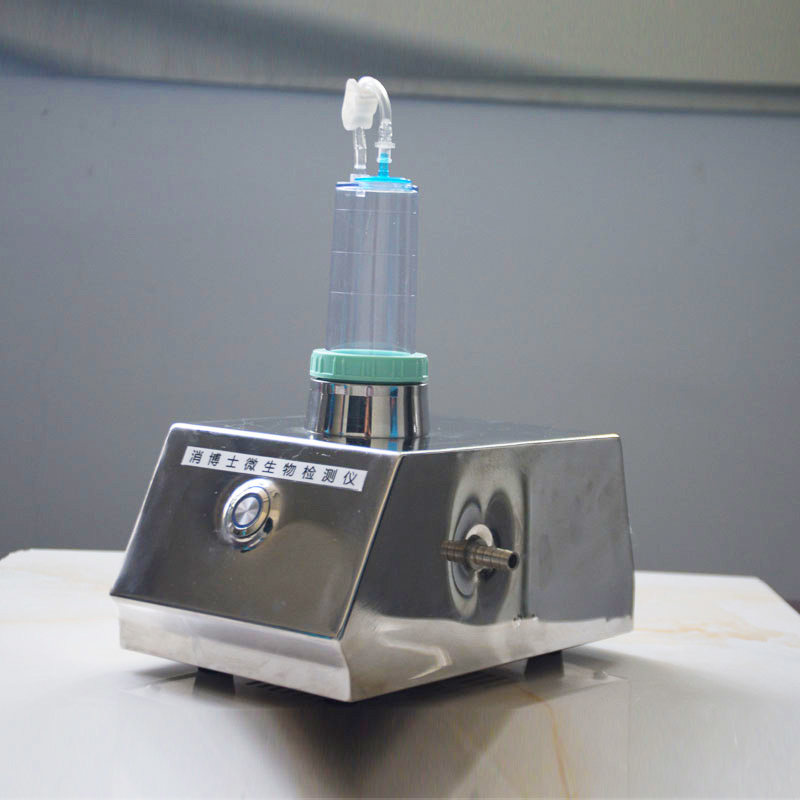

The NAI-XDY-P type endoscope microbiological testing device is used in conjunction with the endoscope sampling device. Samples are taken using the NAI-XDY-PQ sampling pump, and after sampling on-site, the cup is sealed and then transferred to the microbiology laboratory. The NAI-XDY-P type microbiological testing device is used for filtration, retaining microorganisms on the filter membrane for culture and counting. It is suitable for microbiological load testing of endoscopes in the medical and health industry.

Endoscope Microbiological Testing Device Manufacturer

Performance Features:

1. Built-in micro high-performance diaphragm pump, no need for a filtration bottle, greatly reducing the space occupied on the operating table, making it more convenient to use;

2. Button switch control with indicator light, simple and intuitive operation;

3. Simple internal piping, with no dead corners for microorganisms to breed, facilitating cleaning and disinfection;

4. Stainless steel casing polished to a mirror finish, smooth and flat surface, easy to clean and disinfect;

Endoscope Microbiological Testing Device Manufacturer

Technical Parameters:

1. Applicable consumables: Endoscope sampling device

2. Power supply: AC 220V/50Hz

3. Power: 25W

4. Pump flow rate: 0.7L/min

5. Noise: ≤60dB (under load)

6. Weight: 2.5kg

7. Dimensions: 25cm×19cm×14cm (L×W×H)

8. Drainage hose specifications: Inner diameter Φ10mm~Φ16mm silicone tube

Application Fields:

Endoscope sampling and microbiological limit testing in the medical and health industry

Product Principle:

Due to the unique structural characteristics of endoscopes, they are difficult to clean and disinfect, posing a risk of cross-infection among patients. Therefore, it is particularly important to routinely monitor the effectiveness of endoscope cleaning and disinfection to evaluate whether the disinfection meets standards. The 2015 edition of the "Chinese Pharmacopoeia" requires the use of membrane filtration to check the microbiological limits of purified water. This method is also mentioned in the "Hospital Disinfection and Sanitation Standards" (GB 15982—2012) for monitoring disinfected endoscopes. A 50mL elution volume can more fully contact the inner surface of the endoscope compared to 10mL. Combining direct inoculation, membrane filtration, and colony counting will provide a more objective and scientifically effective evaluation of endoscope disinfection quality.

Regulatory Requirements:

The "Technical Specifications for Cleaning and Disinfection of Flexible Endoscopes" (WS507-2016) requires that disinfected endoscopes undergo biological monitoring every quarter. The sampling method for disinfected endoscopes described in the "Hospital Disinfection and Sanitation Standards" (GB 15982—2012) is the membrane filtration method: After cleaning and disinfecting the endoscope, use a sterile syringe to extract 50mL of elution liquid containing the appropriate neutralizer, inject it from the biopsy port to flush the endoscope's tubing, and collect the entire volume (a peristaltic pump can be used) for testing. Mix the elution liquid thoroughly, take 1.0mL of the elution liquid for inoculation on a petri dish, and pour 15mL to 20mL of melted nutrient agar cooled to 40℃~45℃ into each dish, incubate at 36℃±1℃ for 48 hours, and count the number of colonies (CFU/item). The remaining elution liquid should be filtered using a membrane (0.45μm) under sterile conditions to concentrate it, and the membrane should be inoculated on a solidified nutrient agar plate (care should be taken to avoid bubbles), incubated at 36℃±1℃ for 48 hours, and count the number of colonies.

When the membrane filtration method is not countable: Total colony count (CFU/item) = m (CFU/plate) × 50, where m is the average colony count of two parallel plates.

When the membrane filtration method is countable: Total colony count (CFU/item) = m (CFU/plate) + mf (CFU/membrane), where m is the average colony count of two parallel plates; mf is the colony count on the membrane.

Required Instruments:

The instruments and materials involved in the membrane sampling method for endoscope sampling include a bacterial filter or microbiological limit testing device (equipped with a filter) and a 0.45μm filter membrane.

Bacterial Filter: Composed of a vacuum pump system, collection bottle, connecting tube, filtration rack, filtration cup, and flame sterilizer.

Microbiological Limit Testing Device: Composed of a filtration drainage box, flame sterilizer, and filtration cup.

Filtration Cup (Filter): Commercially available filtration cups are made of stainless steel and modified PP materials, both of which can be sterilized using moist heat and flame sterilization.

Filter Membrane: The "Chinese Pharmacopoeia" stipulates that the pore size of filter membranes used for sterility testing should not exceed 0.45μm, with a diameter of about 50mm. The filtration capacity of a 0.45μm filter membrane can reach over 99.99%, and it causes less damage to microorganisms compared to a 0.22μm filter membrane, which is more conducive to the recovery and cultivation of microorganisms. Commercially available 0.45μm filter membranes come in diameters of 47mm and 50mm. Note that the filter membrane should be sterilized before use.

Working Principle:

Using the principle of vacuum pump negative pressure filtration, a pressure difference is generated on the microporous filter membrane (sterilized before use) inside the filtration cup. The test sample in the filtration cup passes through the microporous filter membrane due to the pressure difference. The microporous filter membrane has a complex honeycomb structure, which can intercept microorganisms even below 0.45μm, thus efficiently recovering microorganisms and retaining any microorganisms that may be present in the test sample on the filter membrane. The pore size of the 0.45μm filter membrane is conducive to the recovery of microorganisms, and the culture medium easily permeates the filter membrane, facilitating bacterial culture.

Filtration Method Operation Steps:

1. Take out the sterilized filtration cup and connect it to the main unit, ensuring a good seal;

2. Inject the remaining elution liquid after direct inoculation into the filtration cup, and perform negative pressure filtration using the vacuum pump. The elution liquid in the filtration cup passes through the microporous filter membrane (sterilized before use) due to the pressure difference, retaining any microorganisms that may be present in the elution liquid on the filter membrane.

3. Remove the filter cup, use sterile tweezers to take the filter membrane, and transfer it to the prepared solid culture medium with the bacterial side facing up, laying it flat. The filter membrane should be in complete contact with the culture medium, and there should be no air bubbles (bubbles will affect the growth of microorganisms);

Get a Free Quote

Please fill in the contact information and your needs, we will arrange professionals to contact you!